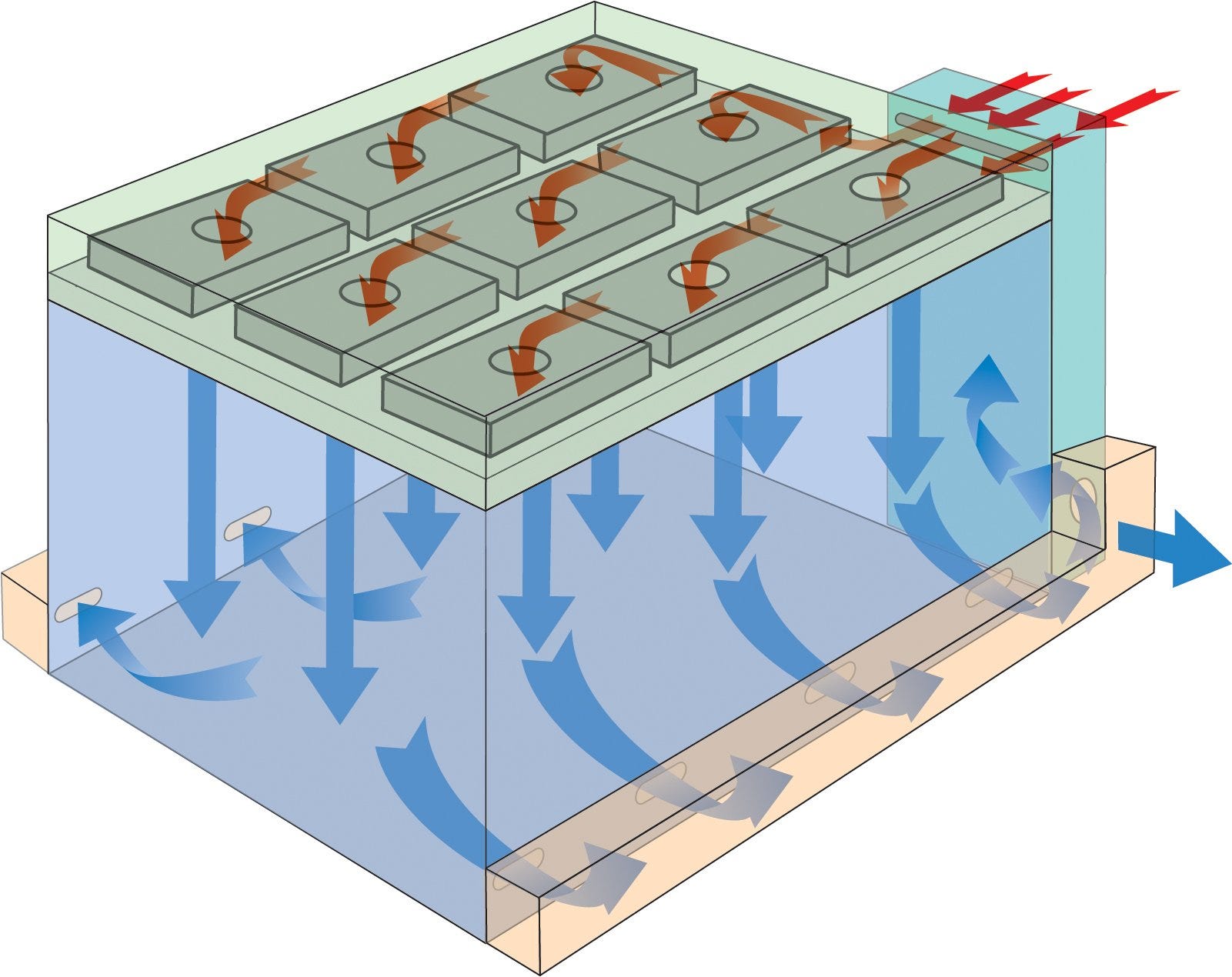

Air balancing adjusts airflow in the air handling systems to achieve design airflow room air exchange rates and pressure cascade airflow visualization studies qualitatively verifies airflow direction using a source of visible fog tss has several fog options including carbon dioxide glycol and liquid nitrogen.

Clean room pressure balancing.

The 2014 fgi guidelines standard 170 2013 provides lists of rooms that should be positively or negatively pressurized with respect to surrounding areas.

This means that in most facilities the cleanrooms air handling units ahu consume over 60 of all the site power.

Negative pressure is used to contain airborne contaminants within a room.

There are different cascading levels of positive air pressure from the cleanest rooms at the highest pressure down to the gown room or airlock room.

Positive air pressure means the cleanroom or rooms are pumped up with more filtered air then the surrounding space outside the cleanroom s.

Positively pressurized rooms are usually designed to protect a patient clean supplies or equipment within the room.